Environmental Testing & Water Testing Laboratory for Industries

With technological laboratories and ISO 17025 certification, we provide environmental analyses to verify the quality of water, wastewater, soils, sediments, and waste. Count on us to meet the most demanding quality and sustainability standards!

Customized environmental testing solutions for your business

EP Aqua is a leader in environmental analysis, specializing in industries aiming for compliance with strict environmental regulations.

Our laboratories serve the U.S. market, operating under ISO 17025 certification, which reflects our genuine commitment to reliability, precision, and safety for every project.

We conduct environmental testing for the following matrices:

Water

Monitoring the quality of drinking water, groundwater, and surface water.

Wastewater

Control and compliance assessment of industrial wastewater.

Soils and Sediments

Detailed testing to identify contaminants and contaminated areas.

Waste

Classification of solid and liquid waste, including toxicity analysis.

Laboratory and Testing services

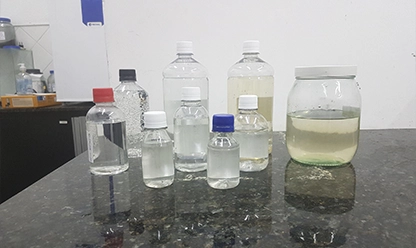

Water Quality Testing

Conducting detailed testing of industrial water and wastewater.

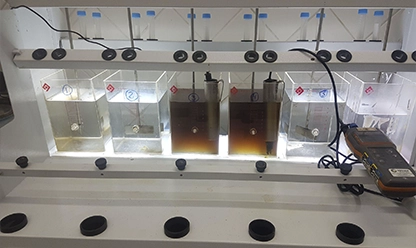

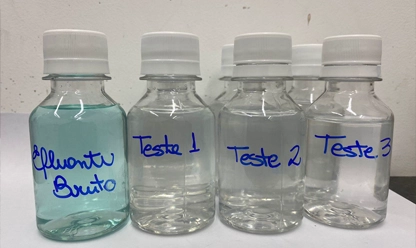

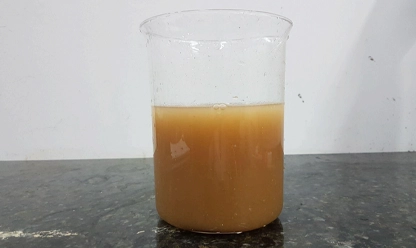

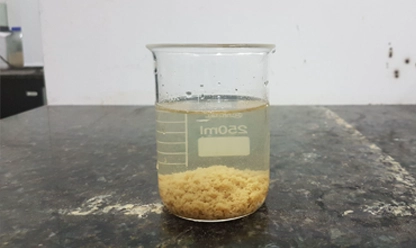

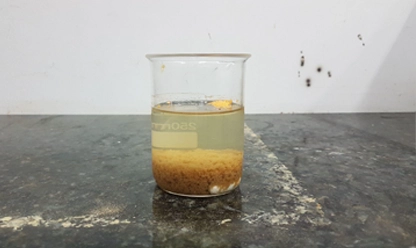

Bench-scale Studies

Simulating treatment processes in controlled lab environments.

Performance Testing

Evaluating the efficacy of new chemicals or technologies.

Our water testing laboratory serves a variety of needs

EP Aqua’s water testing laboratories are equipped to perform detailed and highly reliable tests. With cutting-edge technology and an experienced, qualified technical team, we deliver precise results, ensuring the quality and sustainability standards your industry requires.

Facilities:

- Metals Analysis Laboratory.

- Ion and Liquid.

- Chromatography.

- Physicochemical and Microbiology Analysis.

- Volatile and Semi-Volatile Organic Compounds Analysis.

- Ecotoxicology Analysis Laboratory.

Stay in compliance with the most demanding environmental regulations in the market

Our work is conducted according to the most strict regulations to ensure your operation remains compliant. All EP Aqua analyses adhere to the following standards:

Water

Wastewater

Soils and Sediments

Waste

Benefits of hiring EP Aqua for environmental testing

Here, every environmental test is unique. Check out some of our differentiators:

Technological Laboratories

All laboratories are equipped with advanced technology to perform tests across various environmental matrices.

ISO 17025 Certification

Precise and internationally recognized testing results.

Integrated team

We have engineers, chemists, and biologists to analyze and meet the needs of your industry.

Customized solutions

Our tests are unique, meaning we customize our services to meet the specific needs of each client.

Interested in our services?

Contact us now!

Our team is ready to assist you!

Phone: +1 773-882-5111 | Email: epaqua@epaqua.com